The Spaight Street Syndicate

The Spaight Street Syndicate Iceboat Shop

Daniel Hearn’s reports from his iceboat shop where DNs and most recently, a C Class Skeeter are built and tuned.

Shop Talk from Spaight St. Syndicate: Trust The Engineer…Or Else!

Previously: “That Will Buff Right Out”

Via Daniel Hearn, Spaight Street Syndicate

Trust The Engineer…Or Else!

Since it was determined last weekend at Lake Pepin that I have a weak spine, this weekend it was time to man up. First I removed the ragged skin to the closest bulkheads, sideboard or stringer. Then I cut out the what remained of the old spine. The original T-beam was constructed of 5/8” Sitka, 2-1/2” wide with triangles underneath. I made the new T-beam out of 1” x 3” White Oak with two verticals on the bottom, triangles underneath and horizontally at the bulkhead joints. For additional peace of mind, I added a layer of 45 degree carbon and a layer of biaxial carbon around the entire beam, plus one more layer of carbon on the top. And finally, carbon gussets at each of the corners were the beam and bulkheads meet. This construction should be dramatically stronger than the previous, which would have been fine, had I just followed Pat’s plans.

Rather than using a traditional top-mounted mast ball track, which would have spread the load out across 14” or so, I used a 6” countersunk style. This required the removal of a fair amount of material directly under the mast ball, when the shorter length was already concentrating the load in a smaller area. The mistake I made was not accounting for these impacts. But the countersunk style looked cooler. (That’s what we call “solid” marketing thinking!)

The spine didn’t actually collapse, rather, the track twisted, blowing out the side of the original beam. It was breezy that day on Lake Pepin, so in addition to carrying a bunch of lead, the stays were slacked off, which caused more side load on the mast ball, hence, the twist.

Hopefully the Northwest will be “On” for the coming weekend, so I can give Lorem Ipsum another shakedown, and try to catch Pat!

Spaight Street Syndicate Update: The Other Deuce

And now for something completely different, via Daniel Hearn at the Spaight Street Syndicate.

The World According to Dash

If you’re like me, time always seems to run short when you’re prepping for the first regatta of the season. So, when nature calls, “ain’t nobody got time for dat.” Well, fret no more! Just get yourself a combo rolling work bench/changing station, like my Pappy’s, and do what I do. Drop that deuce right in your pants. Faster than a Struble start, you’ll be back at it before your runner even cools. Critical Hack–Make sure your sanitation engineer clears the bench of any carbon fiber dust. That can be very unpleasant on a fella’s bum.

Spaight St. Syndicate Update: Flat Pack Masts

Mast mania

Daniel Hearn’s mind wanders over to Ikea iceboat mast section…

Spaight St. Archives

Ikea Masts

Ingvar Kamprad built a $40 billion per year enterprise selling furniture in boxes. His future took shape when he realized success depended on the simplest, most cost-efficient distribution from factory to customer. The founder of Amazon, Jeff Bezos, figured out he didn’t even have to make anything to become the richest man in the world (never mind the divorce). He just had to have the best distribution system anywhere.

I’m sure our first billion is showing up in the offshore shell company bank account as I type, now that word is out that you can buy a C-Skeeter mast in a box. If you’re looking for my name in the Pandora Papers, however, don’t bother. The Corp will eventually trace to my wife’s name. She’s the smart one in the family!

Daniel Hearn

Inside Overlap @ Spaight St.

“Two (or insert any number) are just as easy to build as one” has to be one of the top ten commandments of iceboating building. Daniel Hearn checks in with his latest update.

Spaight Street Syndicate Archives

Inside Overlap

When I’m racing catamarans, I like to amuse myself by coming into the starboard gate on port tack. More often than not, some cowboy will come charging in barking STARBOARD!, with gotcha-rage in their eyes, unaware that he has no rights. Makes me laugh every time.

In my basement shop, I am also currently exercising my inside overlap rights. My entitlement is not guaranteed by any rule book, but my wife still let’s me get away with it. She’s been a really good sport about it, but I can tell she’s not amused. I’m afraid by the time first ice comes, my penance will be along the lines of a hooker leaving a confessional. But it will be worth it!

Just about ready for top skins on both the new C-Skeeter and the fixed wing boat.

Daniel Hearn

“Tool Porn”

“To Bodge (v), to make or repair hastily, to MacGyver”

Spaight St. Syndicate

The Spaight Street Syndicate expands its footprint. Via Daniel Hearn:

A sure sign that you’re a major dork is when certain tools tickle your loins. Guilty. But come on, check out this bad girl! If you’re like me, you’ve been lusting after the perfect re-saw machine since you skinnied your first board. Miss August, Tilly Tannewitz, boasts a 5 horsepower motor that will rip your hardwood quicker than a sailor draining a bottle of rum. She insists that Sitka is for sissy saws, but she doesn’t judge, so she’ll still entertain wuss wood. Touch her button and she slowly winds up until she’s a screaming mad woman just daring you to test her metal. With a 1″ carbide-toothed blade, she’s not slowin’ down for nobody. And if you think you need a rounded fence to keep her tracking down the center, forget about it! Set your thickness, and she’s as straight and true as they come.

Tilly is a relatively new addition to the Bodgery, a community shop that I joined just before COVID. Until now, I’ve never found an economical resource for re-sawing lumber. By the time I would pay a set-up fee and then the hourly rate for cutting at a professional shop, it would still be cheaper to waste a lot of wood in the planer. At $12 per board foot, I just couldn’t do it. So, on my current projects, I ripped the boards to 4″ width, then re-sawed, then planned, then glued the boards back together to get the widths I needed. Material efficient, but labor intensive. Tilly can resaw up to 13″ of hardwood, barely breaking a sweat. I’ve completed my Tilly training, so if you need something re-sawn for your next iceboat build, feel free to hit me up.

A few weeks ago, fellow C Skeeter builder Pat Heppert came to Madison to pick up some high-tech foam to build C Class Skeeter masts. The day started in the original compact basement workshop of the Spaight Street Syndicate, then over to the Bodgery to cut the foam, and then finished at the SSS Launchpad shop.

Getting Framed 2: Still Somewhat Confused

Previous: “Getting Framed”

Pat Heppert checks in with a note about his summer project, a new C Skeeter build and his continuing travails with “ACME” customer service.

Wide Hull Somewhat Explained, Still Confused

The ACME Corporation. Wide selection, instant delivery, questionable quality.

The next shipment arrived from ACME Iceboats Inc., and now it is clear why the frames for the new hull are so messed up looking. The mainsheet assembly actually is about a foot and a half wide. But it seems to have three ropes instead of just one and definitely doesn’t seem to belong on an iceboat. May have been a shipping error. So I got on the phone with customer service again, and they insist that this is what I ordered. How exactly do you expect me to deal with three ropes in the cockpit? “Well, sir, the problem is that you failed to also order our rope-less cockpit conversion upgrade”. They didn’t have pictures of this in the catalog; apparently, it is still under development and doesn’t come with a warranty. Again with the credit card, will see what shows up. But what are all three of these ropes for? “Sir, you need to pull on one of them for more power and pull on the other one for more speed.” That explains two of them, but then I asked what is the third one for? “You pull really hard on that one when you want to beat Daniel Hearn.”

Pat Heppert

Getting Framed

Pat Heppert’s next Class C Skeeter build begins with Acme, where “Quality is our #1 dream.”

The other day I was so inspired by everyone else’s summer iceboat projects that I had to start one of my own. So I went on the internet and ordered up a complete iceboat frame kit from ACME Iceboats Inc. (www.acme-iceboats.com).

When the UPS driver showed up with the big box, excitement quickly turned to disappointment. This doesn’t look anything like what I ordered, so I called customer service to complain. Why are all the frames black, and why did you overcharge my credit card? Customer service said, “This is because your order clearly specified you wanted the INSANITY option” No idea what that means, but it seems like a Dan Clapp reference. When I asked why all the forward frames clearly looked about 10% shorter than the plans, customer service started getting rude and said, “Well, sir, we are fully expecting you to lose some weight before next season.” FAT CHANCE of that happening.

Then I inquired why the aft frames didn’t seem to look anything like the plans. The tail end looks like it is going to be about a foot and a half wide and tapering down to almost no height at the plank. Why in the heck would any self-respecting front-loader possibly be this wide? The discussion went South, and customer service ended the call by saying, “If you are having so much trouble absorbing the simple concept of how to build an iceboat, then you are just going to have to order up our brand new mainsheet assembly and see how it all comes together.” I have no idea what this means, so I just pulled out the credit card and obeyed—no idea what is coming in the next shipment.

Pat Heppert

C-Skeeter “Drifter” I-291

Groundhog Day

Iceboat shops are busy this spring, including Daniel Hearn’s Spaight Street Syndicate. Here’s the latest report.

Is it Groundhog Day, or is this one of those automated Facebook anniversary posts? Well…neither. This is “Weak Moment,” the second C-Skeeter that will come out of the Spaight Street Syndicate. Wisconsin’s C-Skeeter Fleet is doubling in size! A different butt will be seated in the “Original Gangsta/Black Ice” when we’re back in-season.

I must clarify that it makes me uncomfortable talking about other guy’s butts, but I’ll reveal that the owner of this one knows how to make all sorts of sailboats go fast. Whether he’s at the helm, or helping one of his customers. I’ll leave it up to him to expose his butt. Just doesn’t seem appropriate for me to encourage such behavior. At least from another dude.

Not much will be different with boat #2. Hard to improve on Pat Heppert’s excellent design, though Pat is exploring the next generation. The evolution of “Drifter” will be called “Traveler.” Hint…hint. Maybe he’ll shoot Deb some post content to share what he’s been up to. [Yes, please, Ed.]

Weak Moment will be 7% smaller in height and width. That was my original intent with boat #1. In fact, I had completed a full set of bulkheads before getting cold feet hearing stories of claustrophobia. So, I started over. I would have been fine, but I didn’t know any better at the time, so I stuck the work on the shelf. Turns out, it gave me a nice jump start on boat #2.

Winging It

UPDATE: The incorrect photo (now below) was used in the original post. The post has been edited with the correct photo.

Previous: Introducing WING

Iceboat shop news from Daniel Hearn:

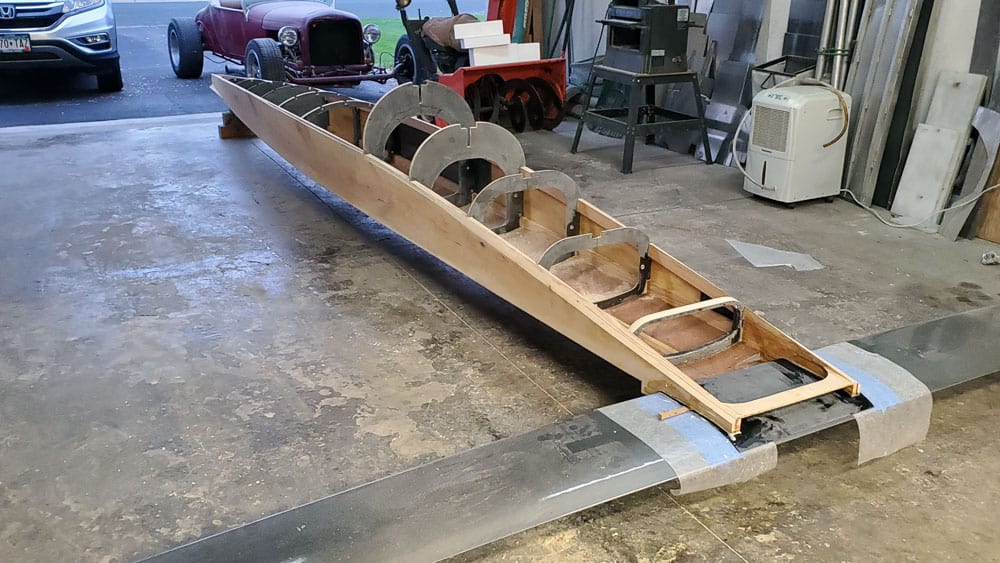

Winging It

It’s always good to surround yourself with people who are smarter than you. With the C-Skeeter, I buddied up to Pat Heppert, and so far, he’s still taking my calls and responding to my texts and emails. When I got intrigued with fixed wing boats, inspired by Dan Clapp’s W28, I reached out to Wing Wizard, John Eisenlohr, who lives in Montana. I had the pleasure of meeting John and some of the other Montana Ice/Dirt Cowboys on our last trip to Fort Peck. Before I knew it, my W28 wanna-be with DN parts had morphed into a 18 ft. tapered wing and flap, with 30″ removable top sections. Plus, a largely enclosed 13 foot hull, 6 foot springboard, and a 12 foot wide plank. I think they call this phenomenon, “project creep.” What is it with iceboaters, anyway? In the immortal words of Dan Clapp himself, “it’s not like we’re racing!”

Here’s a shot of my main wing as it sits now. I’ve just installed the leading edge pieces, but have yet to shape. My hinge boxes are also ready to be installed on the appropriate ribs. After that, I’ve got some additional internal reinforcing to do, and it’s on to skinning. John normally installs the leading edge blocks after the skinning, using ropes with tourniquet-type devices. I decided to mount leading edge blocks first, so I could just use clamps. Guess I’ll find out if this makes the skinning more difficult.

Spaight Street Syndicate Update: Chicks Dig It, Plane It, Sand It, and Glass It

The Spaight Street Syndicate has a guest columnist this week, DN sailor Erin Bury US5397:

Since the December Spaight St. Syndicate wrote about me, I bought my own iceboat (DN 5397) and sailed it on two occasions – the day I bought it and at the U.S. DN Nationals. At Nationals, it seemed like anything that could go wrong did go wrong – boom jaw broke off, outhaul on the boom that was loaned to me in the wake of the broken boom jaw disappeared mid-warmup (sorry Daniel), and I was catapulted from my DN in a 40 mph gust. What I learned – my boom jaw was overtightened, things can shake loose on chunky ice, and how far a 109-pound human missile can fly when launched 30-40 mph. The launch was due to my plank being too stiff for my body weight and this would need to addressed in order for me to stay competitive (and in my boat).

It may be indelicate for a lady to discuss her weight, but in this sport, weight matters. (Plus, let’s be done with body shaming already.) In ice sailing, one can use her weight to her advantage. An ice sailor gets to tailor her boat to her body instead of tailoring her body to her boat. Imagine having precise input on how something fits you and you do not have to change anything about yourself to make it happen. Cue plank shaving!

Over the course of a weekend, Daniel Hearn (DN 5352, walking encyclopedia of all things sailing, ranked seventh internationally as of the 2020 Gold Cup, and a killer catamaran sailor) and Dave Shea (motorcycle number 426, engineer who races dirt bikes on the ice and motorcycles in the road race circuit) helped me customize the plank on my DN for my weight. First, we measured how much it was bending under my weight, which was around 21 millimeters, while the ideal range is 42-44 millimeters (translation: I was having zero impact on it). We decided on an arc that could be described as “sexy” and began planing the plank. After shaving off large chunks, we started sanding. Once we achieved the desired shape, it was time to set it in stone (or glass). Once the fiberglass was set, it was time to sand it again to remove stiffness and maintain that “sexy” shape. The goal is to have it ready in time for the Western Region Championship; thanks to Daniel and Dave this will be possible.

These are usual growing pains of buying a new toy and learning a new sport. When trying something new, I ask myself “What would I do if I wasn’t afraid?” I’d get flung from my iceboat a hundred more times if it means I get to learn something. I cannot wait to get out on the ice to see how my boat performs and what I am capable of with a new boom jaw, a secured outhaul, and a newly formed and customized plank. Anything worth doing will come with challenges and opportunities for growth. As my late grandma/best friend/inspiration (who was third in the world as an All-American triathlete) would say, “Live while you are alive.”

Thank you to Dave Shea for being hands-on in helping with this new endeavor and supporting this little lady at the helm!

Extra special shoutout to Daniel Hearn who is a marvelous sailing mentor. I would not have had access to the same resources nor be exposed to as many opportunities in ice sailing. Thank you for all you do for the sailing communities and for supporting newbies like me!